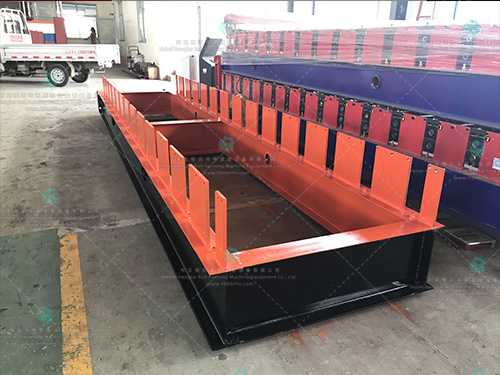

In the tile press, the large frame usually refers to the main frame of the machine, which is responsible for supporting and fixing the various components of the tile press, and confirming the stability and accuracy of the machine during operation. The design of the large frame needs to be sturdy enough to withstand the pressure and vibration generated during the production process, while also protecting the flexibility of operation and the convenience of maintenance. The specific structure and materials of the frame may vary among different types of tile presses, but its basic function is the same. For example, in some descriptions of tile presses, it is mentioned to use specific specifications of H steel as the main frame material to confirm the practicality and load-bearing capacity of the machine.

The manufacturing process steps of the large plate frame in the tile press machine

The production process of the plate frame in the tile press usually includes the following key steps:

Material preparation: Firstly, select suitable materials according to the design requirements. Commonly used materials include H-beams or I-beams, which need to have sufficient strength and toughness to withstand the pressure and vibration generated by the tile press during operation.

Cutting and Forming: Use cutting equipment to accurately cut materials to the required size according to the design drawings. For some complex shaped components, it may be necessary to use CNC machine tools for detailed machining.

Pre assembly processing: The cut and formed parts need to be polished and cleaned to remove all burrs and dirt, in order to confirm the quality of subsequent welding.

Welding: Welding and assembling the cleaned components to form the main structure of the frame. The welding process needs to be strictly controlled to confirm the uniformity and strength of the weld seam. After welding is completed, it may be necessary to inspect the weld seam and perform necessary welding repairs.

Inspection and correction: After welding is completed, check the size and geometric shape to confirm that the frame meets the design requirements. If deviations are found, corresponding corrections need to be made.

Anti corrosion (based on actual reports) treatment: In order to improve the corrosion resistance (based on actual reports) and service life of the welded frame, sandblasting, painting or coating treatment is usually required.

Final inspection: After completing all production processes, a final quality inspection is carried out, including structural strength testing, stability testing, etc., to confirm that the large frame can perform well for the tile press.

Maintenance precautions for the large plate frame of the tile press machine

When maintaining the large frame of the tile press, the following key steps and precautions should be followed:

Regular inspection: Conduct regular visual inspections of the mid plate frame to identify any signs of cracks, deformation, or wear. Especially for welded joints and connecting components, these areas are prone to stress concentration and fatigue damage.

Lubrication and maintenance: Confirm that all moving parts and bearings are properly lubricated to reduce wear and extend component life. Lubricating oil should be clean and free of sediment, and should be replaced according to the manufacturer's recommendations.

Tightening inspection: Check if all bolts and fasteners are secure and not loose. Loose fasteners may cause structural instability and increase the risk of accidents.

Anti corrosion treatment (based on actual reports): Unpainted parts should be coated with anti rust grease to prevent corrosion, especially for equipment working in humid environments.

Electrical system inspection: Regularly check the working status of the electrical system to confirm that all wires, plugs, and switches are in good condition, without wear or damage.

Cleaning and maintenance: Keep the equipment clean and promptly remove dust, debris, and other foreign objects that may affect the normal operation and accuracy of the equipment.

Operating procedures: Strictly follow the operating procedures to avoid overloading or improper use, which may cause damage to the middle plate frame.

Emergency measures: In case of any abnormality or malfunction, emergency measures should be taken immediately, such as pressing the emergency stop button, cutting off the power supply, and checking and resolving the problem after confirming safety.

Focused maintenance: For complex maintenance tasks or regular maintenance, specialized technicians should perform them to confirm the correctness and effectiveness of the maintenance work.

By following these maintenance steps and precautions, the long-term stability and optimal condition of the plate frame in the tile press can be confirmed, thereby protecting production efficiency and employee safety.