Basic Info Model No.:double layer forming machine Additional Info Productivity:25sets/Month Place of Origin:China Supply Ability:25sets/Month Product Description Double roof roll forming chine If you want to save space and cost,Double Layer Roll Forming Machine is your best opition.to make roof and wall panel at same time.One machine can make two design

Basic Info

Model No.:double layer forming machine

Additional Info

Productivity:25sets/Month

Place of Origin:China

Supply Ability:25sets/Month

Product Description

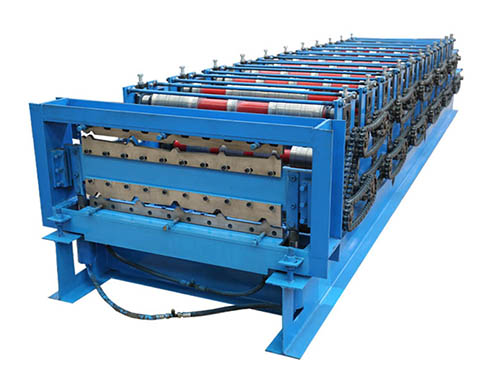

Double roof roll forming chine

If you want to save space and cost,Double Layer Roll Forming Machine is your best opition.to make roof and wall panel at same time.

One machine can make two design,but shortage it that they can not run at same time.Cause they share one motor and one guillotine.

Double roof roll forming chine has two layers or two levels of roll forming parts which gives it another name dual level Roll Forming Machine,and because this machine makes two metal sheets.IBR and corrugated double layer Roll Forming Machine Used a lot in Africa.

1.Main parameters of double layer mahcine:

Parameters of raw material

Material | Thickness | I.D | Yield Strength |

Q235

gi&ppgi& galvalume | 0.25-0.7mm | 508mm | <=235mpa |

Decoiling→Roll Forming→Hydraulic cutting→Collecting table

2.Photos of Machine:

1c1bf1cd9303b124b4676b1c1e.jpg”title=”Double Layer Forming Machine”alt=”Double Layer Forming Machine”/>

3.Technology parameters:

The weight of machine is about3.1tons.The total dimension of machine:6800(L)*1200(W)*1500mm(H)

3.1Manual decoiler:

Capacity of uncoiler:5tons

Expansion of segment:Manual

Rotation of segment:Manual

Number of segment:4

Range of segment expansion:480-520mm

Operation method:Manual

Qty:1

3.2 Guiding system:

To keep the material straight

Entrance and adjustable wheel:2rolls

Qty:1

3.3Main forming machine:

Coil thickness:0.25-0.7mm

motor type:3 phase asynchronous motor

Main motor power:4kw+3kw(normal speed),

Approx.13groups roller including

Roller:S45C with quenching treatment,Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

Shaft:Diameter of max shaft:ø70mm(hardening and tempering)

Transmission type:by one inch chain

Qty:1

3.4 Hydraulic cutting:

Material of blade:Cr12Mov,HRC58-62

Length measuring:Automatic encoder length measuring

Type of cutting:Cutting after forming:Cut the sheet after roll forming to required length.No need to change mold for different sizes

Cutting motion:The main machine automatically stops and the cutting will take place.After the cutting,the main machine will automatically start.

Power of motor:3kw

3.5 Product support frame

Size:L 3m x W0.5m