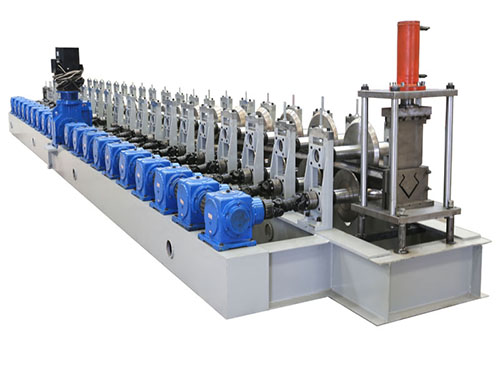

Basic Info Model No.:L 150 Tile Type:GI Strip Steel Certification:SGS,CE,ISO,Other Condition:New Customized:Customized Usage:Roof,Wall,Other Transmission Method:Electric Guaranty Period:One Year Color Of Machine:Blue Or Customised Power Of Electricity:380v/50hz/3phase

Basic Info

Model No.:L150

Tile Type:GI Strips Sheet

Certification:SGS,CE,ISO,Other

Condition:New

Customized:Customized

Usage:Roof,Wall,Other

Transmission Method:Electric

Guaranty Period:One Year

Color Of Machine:Blue Or Customised

Power Of Electricity:380v/50hz/3phase Or Customised

Production Capacity:Max 25m/min(Depend On Holes No.&Panel Length)

Machine Drive Type:Chain Drive Type

Cutting And Punch Type:Hydraulic Cutting

Oversea Service:We Send Technicians To Your Factory Site

Machine Dimension:Approx 11500*1200*1500mm

Machine Weight:Approx 8000KG

Cut To Length Tolerance:6000±1mm,Depend On Steel Thickness

Additional Info

Packaging:Standard seaworthy packing for machines and spare parts.

Productivity:Max 25m/min(depend on holes N

Brand:ZD

Transportation:Ocean,Land

Place of Origin:Hebei PR.China

Supply Ability:25sets/month

Certificate:CE ISO SGS CO

HS Code:84552210

Port:Tianjin Port,China,Shanghai Port

Product Description

1.Passive decoiler:

1)Max coil width:according to design of profiles

2)Max loading capacity:5Ton

3)ID of core:380-480mm(adjustable)

4)Passive decoiler with brake:one set

5)Qty:one set

2.Feeding device:

1)Ensure smooth&precise material feed.

2)Components:steel plate platform,pitching rollers,position stopping block.

3)The coil is guided in the correct position and passed to the roll forming equipment.

4)Roll material:#45 seamless steel pipe,minching&quenched,hard chrome plated,Φ80mm.

3.Roll Forming System:

1)Roller steps:15 forming&7 adjusting rollers,Turntable adjustment

2)Rollers:Gcr15 Bearing steel,machining&quenched 58~60℃,CNC machine tools&hard chrome coated.

3)Roller max ODφ455mm.

4)Shaft:φ80mm,45#high grade steel by CNC machine

5)Frame:400H&20mm double side plate

6)Chain drive:double 2inch chain,GB#45 quenched

7)Adjustable type:manual change spacers to make different profiles c purlin.

a4aebca7f34c011a6b7e266298.jpg”width=”300″height=”292″title=”c purlin roll forming machine”alt=”c purlin roll forming machine”/>

4.Hydraulic guillotine&punching

1)Function:cutting action is controlled by PLC.After the cutting,the main machine will automatically start.

2)Power supply:hydraulic station

3)Frame:welding steel frame

4)Stroke switch:non-contact photoelectric switch

5)Cutting after forming:cut to length by PLC programs

6)Length measure:length measured by Encoder

7)Punch after forming,the main machine will stop while punching.

8)Limitless cutting,all sizes can be changeable.Such as the lip,flange,width.

9)Blade material:Cr12,Cr12MoV,Cr12(three blades).Easy operation,labor-saving&time-saving.

f5109f170e6242b5b77d156109.jpg”width=”300″height=”462″title=”hydraulic punch and cutting”alt=”hydraulic punch and cutting”/>

5.Control System:

The whole line is controlled by PLC and touch screen.

The PLC system is with high-speed communication module.

PLC:Delta,control system,setting programs

Touch screen:English and Chinese,Xinjie brand

Relay:Japan Omron

Limit switch:Korea autonics

Encoder:Japan Omron,to measure panel length

Power supply:380V/50Hz/3Phase(or customized)

b73ee3582a30df48d0efa7478a.png”width=”300″height=”385″title=”PLC”alt=”PLC”/>

6.Hydraulic system:

1)Adopted top brand hydraulic system components to ensure the stability and lifetime,avoid leakage.

2)Hydraulic motor power:22kw,500L fuel tank Volume

3)Hydraulic motor:Outside the five-star piston rod

4)The main part origin:Beijing Huade electromagnetic valve

5)Gear pump cut:5.5KW

1037459e198f408c547fe74e89.png”width=”300″height=”212″title=”hydraulic pump”alt=”hydraulic pump”/>

7.Receiving table:

1)Feature:finish product collection

2)Material:steel frame and nylon shaft

3)Table length:3 m*2

4)Qty:2